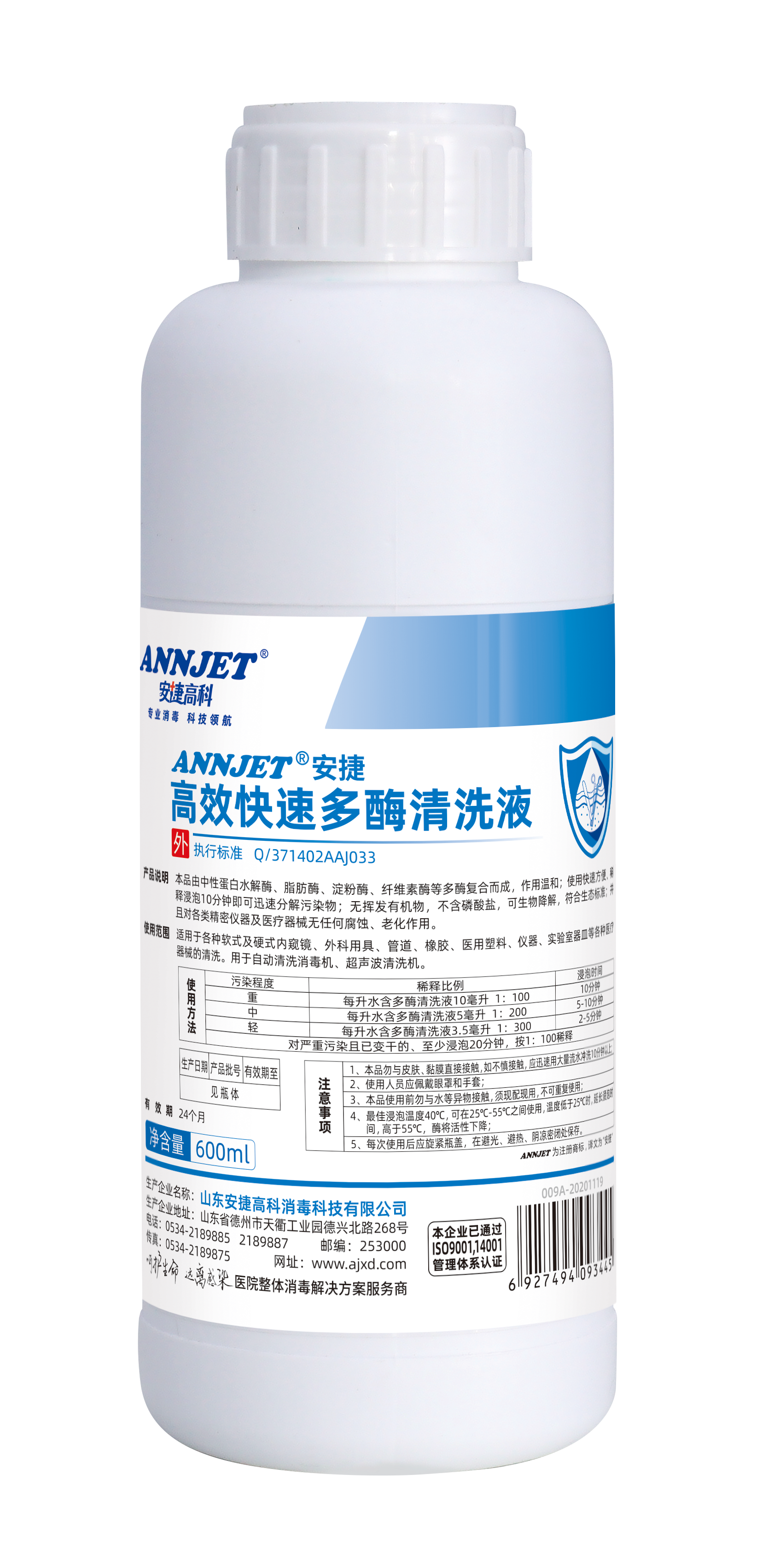

Medical multi-enzyme cleaning solution

Release time:

2022-03-07

Medical devices and supplies in the operation process will contact the patient's blood and tissue, will also be contaminated with chemical agents, body fluids and dirt. The lumen of the instrument is also likely to be filled with these contaminants. These medical devices and supplies must be disposed of to ensure safety before being used by the next patient. Articles that come into contact with human body fluids (high-risk articles) must be sterilized, but sterilization alone is not enough. When the instrument is contaminated with sterilized dirt, chemicals or itself is corroded, they can still pose a health hazard to the patient. Therefore, those potentially dangerous dirt and surgical residues must be removed, and cleaning is a very important step before sterilization. Specifically, the reuse of medical through cleaning, can achieve the following effects:

1. Remove all visible dirt, tissue, blood and foreign objects

2, reduce the biological load

3. Prevent the corrosion of instruments

4. Ensure safe access to equipment and supplies.

multi-enzyme cleaning agent method

The nature of the medical device determines its cleaning method, and the manufacturer of the device should provide the user with a description of the cleaning method and an updated version. Cleaning can be done manually, by machine or both. The selected cleaning method must be effective, do not damage the function of the medical device and do not bring occupational hazards to the operator.

1. Manual cleaning

Any medical device should be able to be disposed of by hand cleaning. We usually recommend manual cleaning of delicate or complex instruments, including minimally invasive surgical instruments, instruments with lenses, and aerodynamic drills. Instruments that can be submerged should be carried out below the liquid level to avoid aerosols; for instruments that cannot be submerged, aerosols should be avoided as much as possible and rinsed and dried according to the instructions of the instrument manufacturer. Suitable temperature of water and cleaning agent (preferably at 27 ℃-44 ℃, not more than 60 ℃) can avoid protein coagulation, so as to help remove. The temperature of the soaking solution shall be monitored and recorded. Water hardness, pH, temperature and dirt may affect the effectiveness of the enzyme-containing cleaning agent, so the instructions provided by the cleaning agent manufacturer should be followed. After the cleaning is completed, sufficient rinsing is carried out to remove the dirt and the residue of the cleaning agent.

2. Automatic cleaning machine cleaning

Machine cleaning refers to the automatic cleaning and rinsing process to achieve the removal of dirt and microorganisms. Some types of automatic cleaning machines can also kill different kinds of microorganisms by means of thermal disinfection or chemical disinfection. There are many types of cleaning machines, and some are also designed to handle special medical equipment, such as endoscopes.

The components of blood are water-soluble proteins. In machine cleaning, if these water-soluble proteins are not removed in the cleaning stage, they will be denatured in the subsequent thermodynamic disinfection stage. Denatured proteins are difficult to remove in subsequent washing processes. It is therefore essential to remove blood, body fluids and tissue debris during the cleaning phase, otherwise the ensuing bioburden poses a risk of infection to the worker.

RELATED INFORMATION